Exeter Stories

Exeter folk and friends in their own words - 1890's to the 1990's │ << Previous story │ Next story >> │

Also see Express and Echo report of the Ice-Factory fire

Cyril Brown`s - industrial Shilhay and Exe Island 1920s

My father had a blacksmiths and millwrights business here and I had the privilege of visiting and working in all the mills and factories here and have collected many stories regarding the history of the mills etc. from their owners as handed down in their families.

First in Bonhay Road we have the paper mills owned by the Pitts family who were well known in the City. Several brothers, two having paper mills (Head Weir & Trews Weir), another owned Carr & Quicks, wine importers and cider makers (he was once mayor of Exeter and lived at Marsh Barton).

Next we have the South Devon Ice & Cold Storage Co. on the Lower Leat. This factory made large blocks of ice in pits in the floor then hoisted them out and cut them up with a circular saw into 1 cwt (50kg) blocks of ice about 8"x8"x20" (20cm x 20cm x 50cm). This factory had a large gas engine for power and they made their own gas by the producer gas process as well as using town gas. The transmission of this power was unique as it was by an endless rope which went around various pulleys and around corners to drive the machinery and the lift to various floors. The upper floors of the building were used for storage of meat and poultry by the local butchers who took and collected meat from there.

Butchers had no fridges then, the only cold room they had was a room with slate shelves where the meat was placed and covered with broken ice which was delivered in a box shaped, horse drawn wagon. The drayman delivered the ice block on an iron shelf strapped around his waist and neck, carrying the block in front of him. I often worked in this factory.

One morning, going to work I was met by Ralph Tucker who worked for Bodley Bros. He said to me "We will not be able to do any more work at the Ice Factory!". I said "Oh, why not?". He said "It was burned to the ground last night". I didn`t believe him and thought he was joking as the ice factory was always streaming in water and everything soaking wet, impossible to burn, you would think. There was also another unfortunate occurrence here - the manager committed suicide by cutting open the gas bag canvas of the engine and putting his head inside.

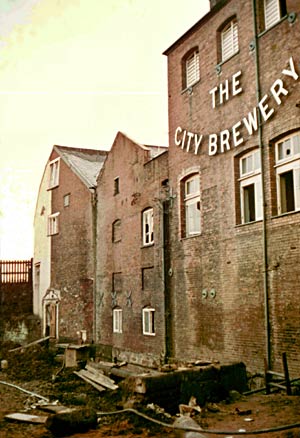

Next we have the City Brewery which had a water wheel to drive all the machinery and the deep well pumps,etc. Adjoining the City Brewery was the Round Tree Mill. This had a water wheel driving a pair of flat millstones as a gristmill. This mill was burned down after being set on fire by the owner who was caught in the act and sent to jail (1906). This mill was then bought by the brewery who put in a water turbine and dynamo to generate their own electric light at 50 volts so as to be safe for use in inspection lamps on leads inside the wet conditions of the vats when being washed out. The brewery was burned down in 1967.

Next we have the Tannery, which only used the water of the leat for washing and processing the leather, being driven by a steam engine and later all electric. This burned down in 1942.

We now come to the Devonshire Baryta Co. This firm ground small yellow pebbles which were mined at Christow in the Teign Valley into a fine powder for making paint and distemper. A large water wheel drove two pairs of heavy flat millstones of French burr stone and some of composition. The mill also had a ball mill driven by a gas engine which was used for the primary stage of the grinding. The finished product was very heavy; you could not lift a bucket full. It was dispatched in small canvas bags stitched up very tight so as not to lose any of the fine powder.

Cyril remembers the mills

This leat (Upper Leat editor) travels unhindered behind Tudor Street, under Bridge Street, to West Gate. Here it picks up an old city waterway that comes from Fore Street, down under West Street and into the leat. As the water has not been retarded till now, there is a deep fast stream which is used by Helliers City Roller Mills, a flour mill using large, cast-iron, grooved rollers to grind the flour. This mill burned down in 1926.

Beside this mill was Upright's Mill driven by a water wheel with a flat stone mill for grist only. After the Roller Mill fire this was taken over by Mr Upright who installed a turbine and a modern roller flour mill there.

Next we have Cricklepit Mill, a water wheel driving a pair of flat mill stones for grist milling, later called French's Mill'

Next is Shears Mill, a water wheel driving a pair of flat millstones for grist milling. Further down the leat was an old skeleton iron water wheel which was reconditioned by my firm and connected by a long shaft to help power the mill. This mill was also burnt down in 1934.

Later, this mill was redesigned and rebuilt by our firm (W.Brown & Son), using the old water wheel driving high-speed vertical millstones. The whole mill was designed to make it usable by one man. A raised floor was used as the sacks of corn could be trucked off and on to lorries without lifting; also, this left 3ft of space under the floors for shafting,etc, and enabled the cats to keep the mill clear of rats and mice. The corn coming into the mill was tipped into chutes in the floor and taken by belts and cup elevator to larger storage hoppers in the roof, then to run by gravity down through the mills and be sacked off. Even the weighing machine was let down flush with the floor so as the operator did not have to lift any full sacks, everything being moved by sack trucks. This mill was still in use 1975. The water wheel was 20ft diameter, 8 revolutions per minute, giving approx 40hp. The two millstones require 15hp at 500 revs, so gearing had to be used to gain the correct speed. The original wooden-tooth wheels were rebuilt and used again, each tooth being fitted and cut by hand on site from apple wood.

© 2007 Exeter Industrial Archaeology Group/David Cornforth

Cyril Brown was interviewed by the Exeter Industrial Archaeology Group in November 1975, during their project to document the area before the new housing was constructed. He worked for the family firm of W Brown and Son, opposite Bodley Bros in Commercial Road. This page is a number of selected extracts from these interviews.

W BROWN & SON Engineers (since 1929 area became Council Yard) : General Engineers, Millwrights and Smiths. In general demand locally, work obtained by private negotiations - no tendering, almost entirely in Commercial Road and Exe Island area. Repair work in Tremletts, mills and sawmills. Eight men employed.

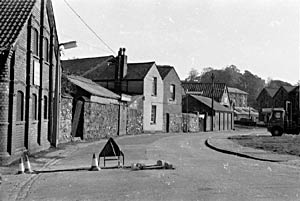

Commercial Road in 1975

Commercial Road in 1975  The Devonshire Baryta Co just below

Cricklepit. Note the gables of the Commercial Road clubs.

The Devonshire Baryta Co just below

Cricklepit. Note the gables of the Commercial Road clubs.  The side of the City Brewery,

Commercial Road. Photos Alan H Mazonowicz

The side of the City Brewery,

Commercial Road. Photos Alan H Mazonowicz

│ Top of Page │